Is it Time to Upgrade Your Pump Station?

By Kurtis DeShaw, PE

Do you have a pump station with a pump due for replacement? Several factors go into this decision when it’s time to replace your pump and what you will replace it with. There are some common triggers for pump replacement and some items to watch out for when selecting your new pump. While there are many factors to consider with an upgrade, some common reasons for upgrading pumps we hear most frequently are:

- Increasing operations and maintenance costs.

- The pump performance has diminished.

- The pumping requirements on the pressure zone have changed over time.

- The pump has exceeded its life cycle.

- The pump has excess vibration or is leaking.

These are frequent issues that can arise in your pump station that prompt replacement plans. Most triggers are straightforward, but some instances require a little more investigation. Operations and maintenance costs or headaches are straightforward and easier to put a price tag on.

On the other hand, several other issues can cause diminishing pump performance. Your pump’s impeller may be worn (possibly due to cavitation, the incorrect impeller material, or just normal wear and tear), or the pump may require maintenance (lubrication, seals, etc.). Or, possibly, air could be trapped in your system, causing diminishing flows. An air release valve would alleviate this issue in this scenario, and a pump replacement isn’t necessary. But issues are not always this straightforward, and out-of-the-box thinking is often required to resolve the diminishing performance issue.

If you have a preliminary engineering report (PER) or master plan, these documents often include a projection for when to change pressure zone requirements. Planning can help create a solution and give you time to budget for these eventual improvements. Pump station upgrades can often slip through the cracks, and upgrades are needed because the station can no longer keep up.

Excess vibration can also cause issues with performance. Alignment testing is a process you can undertake to determine if your pump is aligned correctly. An expert can analyze your pump and identify more challenging vibration issues in unique situations.

Which Pump Shall It Be?

Questions that may be running through your mind at this point might be:

- What type of pump should I select?

- What impeller should I choose?

- What hydraulic performance do we want?

- Were there everyday maintenance items with the last pump that we can avoid with a new one?

- Do we need to upgrade the electrical?

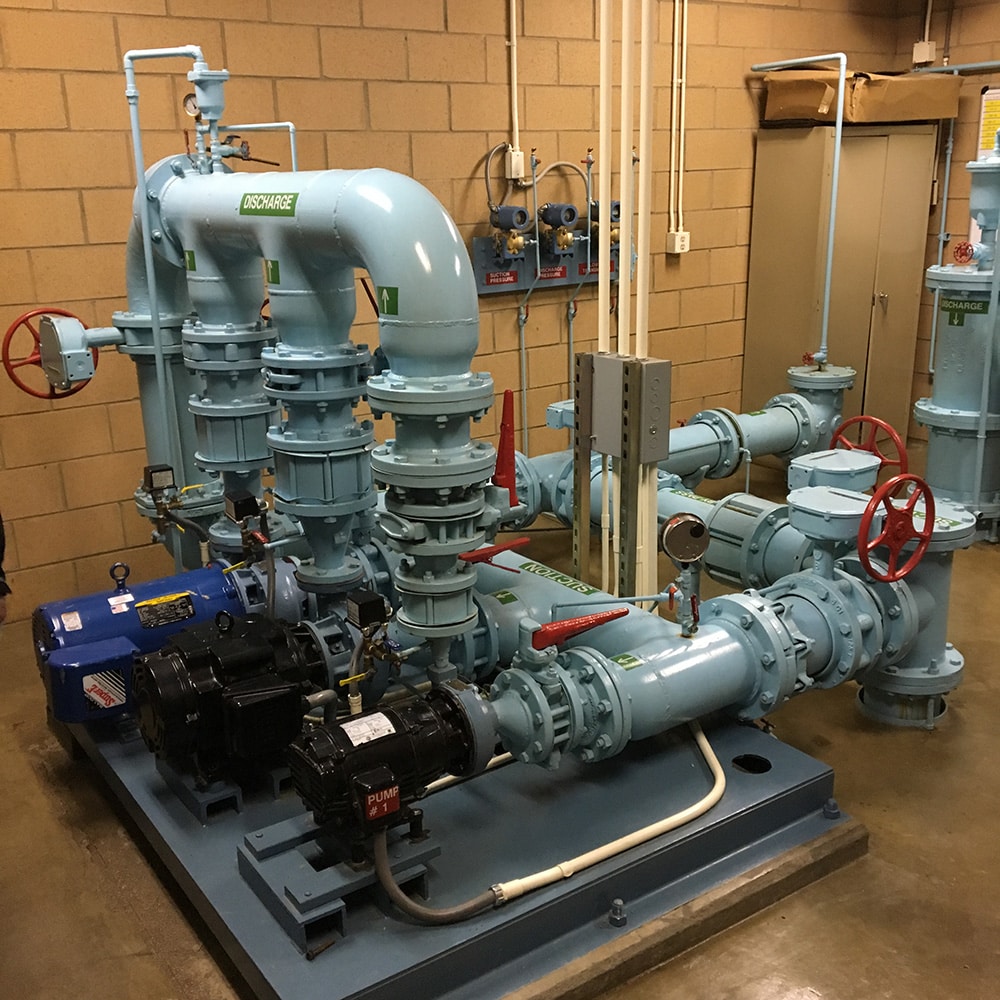

Most of the time, you will replace the pump in an existing pump station with a similar style (horizontal split case, vertical turbine, etc.). Often the same size and sometimes even the same hydraulic performance is preferred.

But you can ask yourself one question to avoid problems: have you had issues with your impeller? Selecting the proper impeller is critical to reducing wear and tear on your pump and optimizing long-term performance. Certain impeller materials perform better under specific situations.

If there are chemicals in your water that may be causing issues, a stainless steel impeller will perform better. And if you are dealing with an abrasive material in your water, such as in raw water pump stations, stainless steel impellers are among the best performers, and cast iron is among the worst.

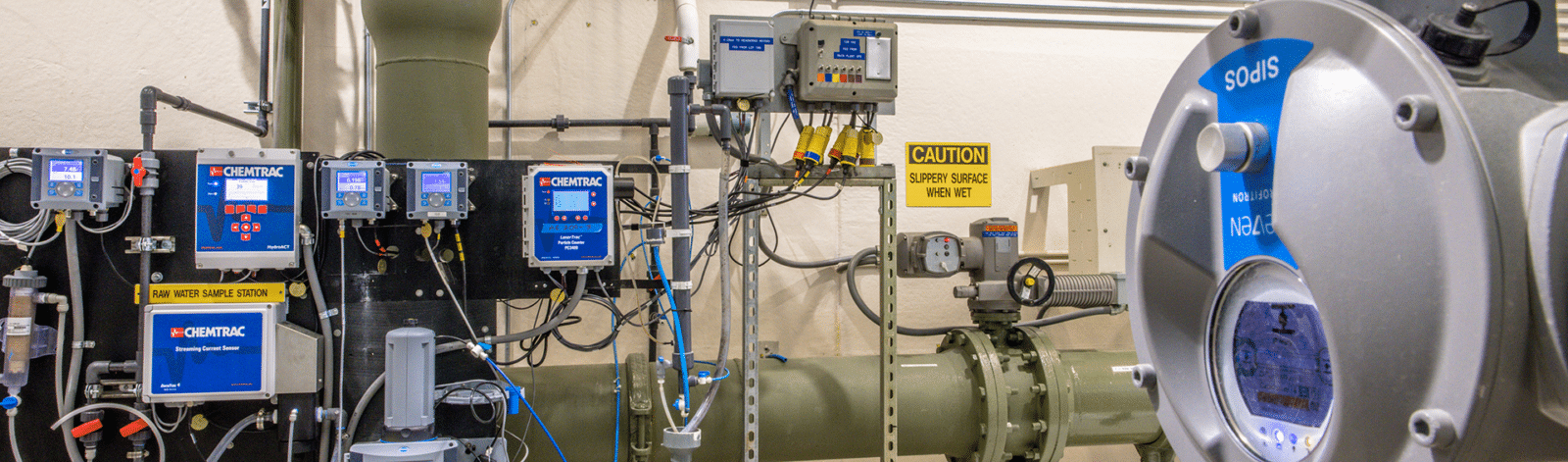

Another consideration is to analyze the pump station’s ability to keep up with increasing demands in the pressure zone. Even if you have a solid grip on your distribution system, performing a hydraulic model may be worth the investment. We have often seen situations when pumps are upgraded to increase demands, but the downstream system wasn’t taken into account, which resulted in multiple breaks in the system due to increased pressures. A larger pump may also require bigger suction and discharge piping, fittings, and valves.

Electrical equipment may also require upsizing if increasing demands dictate a larger pump. This improvement may require modifications to the existing motor control cabinet and wiring, which can be made to any pump station. When tight corridors don’t allow for these upgrades, there are options to move the exterior equipment to facilitate your needs.

You Have Questions, and We Have Answers

A simple pump upgrade isn’t always as straightforward as it seems. Considering several items to lower future operations and maintenance costs would be best. Being mindful of these items and selecting the correct pump will protect the rest of your distribution system. If you need a pump station evaluation or have questions about pump station construction, please contact us at any time with questions.